Notes: For academic institutions, non-profit organizations, or international agencies that wish to collaborate academically, scientifically, or technically with UPA’s FabLab, please contact the coordinators.

We are a digital fabrication laboratory, working with rapid prototyping and advanced manufacturing, with the aim of promoting the use of digital fabrication technologies for the training of highly skilled professionals, as well as contributing to society and the national industry by showcasing the advantages these technologies can offer for both the production and promotion of products. Our laboratory is part of the global Fab Lab network, where we share experiences and projects at regional and global levels.

We teach our Industrial Engineering students to design and prototype their innovation projects using the tools available in the laboratory. We also offer educational robotics classes with LEGO Mindstorms applied to production and logistics processes, Arduino workshops, and a robotics club.

In the Innovation Management I module, the process of conceptualizing, designing, and producing an innovation/invention is developed. Students learn about methodologies and tools for innovation, as well as how to use 3D software to create CAD files (Computer-Aided Design), product renders (visualizations), and technical drawings.

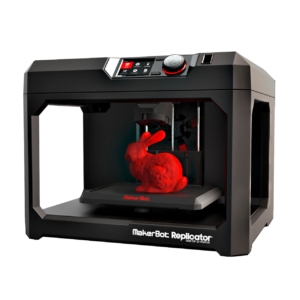

In the Innovation Management II module, students learn how to take the CAD (Computer-Aided Design) files created with design software and transfer them to the CAM (Computer-Aided Manufacturing) process for fabrication, using the laboratory’s CNC machines, such as laser cutting, 3D printers, and CNC routers.

In this final module, students apply all the knowledge acquired in the previous modules, as they prototype their 3D-modeled ideas and manufacture them using the tools available in the laboratory.

Using the LEGO Mindstorms kit, students carry out a practical project in which they simulate a Just-in-Time (JIT) production system.

In addition, workshops are offered to learn programming and to develop projects with Arduino, and the Fab Lab also features a VEX Robotics kit.

We offer digital fabrication services and design and prototyping consulting for entrepreneurs and industrial clients interested in innovating and testing their ideas.

Notes: For academic institutions, non-profit organizations, or international agencies that wish to collaborate academically, scientifically, or technically with UPA’s FabLab, please contact the coordinators.

The gallery showcases some photos of the projects developed at the Fab Lab by UPA students over the past three years.

Fab Lab is the educational outreach component of the Center for Bits and Atoms (CBA) at the Massachusetts Institute of Technology (MIT), an extension of its research in digital fabrication and computation. A Fab Lab is a technical prototyping platform for innovation and invention that stimulates local entrepreneurship.

A Fab Lab is also a platform for learning and innovation: a place to play, create, learn, mentor, and invent. Being a Fab Lab means connecting with a global community of students, educators, technologists, researchers, makers, and innovators—a knowledge-sharing network spanning more than 30 countries and 24 time zones.

Because all Fab Labs share common tools and processes, the program is building a global network—a distributed laboratory for research and invention.

At the Fab Lab UPA, we have digital fabrication machines and traditional woodworking tools, allowing you to manufacture and test any idea. Among our equipment, we have three 3D printers, a 3D scanner, a laser cutting machine, a vinyl cutter, and a CNC router. For the 3D design of the objects to be manufactured, we have licensed CAD software.

In terms of electronics and programming equipment, we have Arduino kits, as well as LEGO Mindstorms and VEX Robotics kits.

It is divided into three areas: a main classroom that has 10 workbenches for CAD (Computer-Assisted Design) classes. The other two areas are dedicated to the use of clean machines (3D printers, laser cutter, 3D scanner, electronic equipment) and dirty machines (CNC milling machine, saw, drills, jigsaw).